News

PROBAT acquires Royal Duyvis Wiener and significantly strengthens the position in the cocoa and chocolate sector

PROBAT acquires Royal Duyvis Wiener and significantly strengthens the position in the cocoa and chocolate sector. Following the recent integration of AC Horn Manufacturing, we now announce the acquisition of Royal Duyvis Wiener, one of the world's leading manufacturers within the global cocoa, chocolate, and nuts & seeds processing industry. With the integration of Royal Duyvis Wiener, we strengthen our position in product and process innovation and expand our technological lead in the food processing sector. To exploit synergies and create integrated solutions for cross-segment projects, the technology transfer between the individual group members will now be significantly intensified. The aim is to further increase market share in the global cocoa and chocolate sector.

The acquisition process has also been challenging in terms of time and content. We are grateful to have FAI as a partner who supported us with their expertise.

PROBAT accelerates strategic development with acquisition of AC Horn Manufacturing

PROBAT accelerates strategic development with acquisition of AC Horn Manufacturing, a world-class producer of premium food processing equipment, based in Texas, USA. With this strategic investment we strengthen our competitive advantage through new technological capabilities and synergies to further penetrate the global food market. We are strategically focused on continuing to invest in our growing business and see the acquisition of AC Horn as a great opportunity to build on a complementary portfolio that will allow us to expand our product offering. By adding new resources and building larger and stronger teams of experts with a wide range of skills, we also underpin our mission to offer our customers individual and future-proof solutions.

As a member of the PROBAT Group, AC Horn will be well positioned to deliver the value and quality that its customers have come to expect - and beyond.

Interpack 2023 - What a Week!

Managing Director Mr Joe Gorman, and our Sales Manager Mr Jeremy Scott

Interpack 2023 is finished, and what a fantastic week it has been! After 6 long years it has been great to get back to Düsseldorf to see our friends, customers, and agents face to face once more.

We have had a wonderful time, and we want to thank everyone who has taken the time out of their busy schedules to come and visit us, we have had some exciting conversations about future projects, and we cannot wait to get stuck in.

We appreciate that in the 6 years since the last Interpack a lot has changed, and it was great to be there, speaking to customers and competitors, and really getting in to the nitty gritty of what is changing in the confectionary world!

Lights out, Factory of the Future!

Hamburg Dresdner Maschinenfabriken brings together the brands HDM, Bauermeister, and MacIntyre as part of the group. With their combined efforts, they can provide single machine and full plant solutions for the processing of cocoa, chocolate, compounds and fillings.

HDM will display their PVS 2000, with over 1000+ installations worldwide. The new design includes a Flavour Monitoring Cockpit (FMC) and actively controlled head space aeration, giving improved safety rating. The very best for conching dark and premium chocolates.

Bauermeister’s grinding and classifying machinery specialises in the particle size reduction of sugar, spices and all manner of food ingredients.

MacIntyre will be exhibiting their newly launched Next Generation RC2000i Refiner/Conche which combines the process steps of mixing, refining and conching in one single machine. This new arrangement incorporates the latest design enhancements and benefits. Also exhibited will be their Particle Analysis Capabilities, used in R&D, which offers real time guidance in the adjustment of parameters to maximise the performance of the Refiner/Conche, achieving the desired results using minimum amount of time and energy and avoiding over refining. The use of the Refiner/Conche for applications such as spreads, cremes, pralines, nut/seed pastes and the processing of rework will also be a talking point, due to its flexibility in being suitable to produce not only the high quality chocolates and compounds but for a variety of applications.

The Group will be showing off their Lights Out, Industry 4.0 Factory of the Future, where customers will be able to see all their latest developments in sensors and controls, where Full Automation is at the forefront of all new designs. Their Stripe Detection Cockpit (SDC) incorporating RGB technology identifies potential over refining and enables automatic adjustment of the 5 Roll Refiner during production, to provide autonomous refining. The industrial proven Partial Adjustment Cockpit (PAC) has become a technical standard in 5 Roll Refining ensuring the required particle size is continuously achieved over the entire roll length at maximum throughput and therefore lowering the cocoa butter usage for the final chocolate. For inclusion in cocoa bean processing, the Humidity Monitoring Cockpit (HMC) is used to prolong the Mailliard Reaction phase in order to accentuate the roasting flavour. Additionally, the Quality Yield Cockpit (QYC) can offer a substantial ROI. Once again using RGB technology, a pre-determined algorithm ensures the minimum amount of nib is lost with the shell and maximises yield.

The smart sensor related Cockpits create many sources of valuable process data for customers around the world, enabling them to actively control quality, improve yield and efficiency and ultimately to save time, energy and money. At a point in time where energy is too precious to waste and time is too critical to ignore, using AI to make automatic adjustments and communications is fundamental to achieving perfect production, releasing people to add real value to the daily operation.

The HDM-team look forward to meeting you in Dusseldorf where we will be exhibiting as part of the overall Probat Group.

MacIntyre Announces NEXT Generation Refiner/Conche Range

Low maintenance, more energy efficient refiner / conche operation

MacIntyre Chocolate Systems announces the new NEXT Generation Refiner / Conche range that sets the benchmark for continuous, low maintenance operation together with greater energy efficiency. The introduction of air pressure seals, combined with IE3 energy efficient motors, mean more efficient running for processing high quality pure chocolate, compounds, creams, spreads, nut pastes and pralines, for example.

Following extensive customer and industry research, MacIntyre has redesigned its market leading Refiner / Conche. Gone are the traditional glands and packing materials and in their place are long life air pressure seals. The incorporation of air pressure seals means zero loss of product due to gland seepage, improving the time and energy efficiency of every batch. Another advantage of the switch to the long life air pressure seals is a reduction in maintenance requirements in this area, significantly reducing production downtime.

Easier Commissioning and Operation

The NEXT Generation Refiner / Conche range is available in four capacities: 500, 1250, 2000 and 3000 kg, including 3000kg and 5000kg Duplex Models. Removal of the glands and packing material gives the refiner / conche a more compact appearance, while the incorporation of a new spherical bearing, combined with IE3 energy efficient motors, mean more efficient running and enhanced surface contact.

All MacIntyre NEXT Generation Refiners / Conches are fitted with Siemens PLC control incorporating enhanced software for flexible running, including remote administration diagnostics, remote commissioning and remote service support - a timely development in times of on-going travel restrictions.

Sets New Low Maintenance and Energy Efficiency Benchmark

“The NEXT Generation Refiner / Conche sets a new benchmark in terms of low maintenance, energy efficiency and production efficacy for manufacturers wishing to produce high quality chocolate and confectionery products,” says Joe Gorman, managing director, MacIntyre Chocolate Systems. "Maximum capacity with minimum energy consumption and zero unnecessary waste have been the guiding principles in the design of the NEXT Generation Refiner / Conche, maintaining its position as the premium method of chocolate processing."

The NEXT Generation Refiner / Conches feature a conveniently removable, easy clean, stainless steel hopper. Steel end plates replace the old cast ends of the Refiner / Conches. Feed pipes are included for intake of liquid cocoa liquor, cocoa butter or fat, allowing customers to easily connect from their liquid raw material tanks to the refiner / conche. Complete systems from block melting through to final storage can also be supplied including full automation. All new models benefit from the easy to install cable harnesses, hygienic cable trays and include safety features for easy installation.

Versatile Product Manufacture and Rework

The MacIntyre Refiner / Conche is the market leader for production of high quality pure chocolate, compounds, cremes, spreads, nut pastes and pralines, for example. Increasingly this versatile machine is now being used for reworking products too; chocolate bars with nuts, crème filled bars, sugar coated lentils and chocolate covered nuts, all can be reworked in the MacIntyre Refiner / Conche. Manufactured in Arbroath, Scotland, the NEXT Generation Refiner / Conche is available through MacIntyre global network of distributors and agents.

MacIntyre Chocolate Systems at Andina Pack Corferias

We are exhibiting the latest developments in MacIntyre Chocolate Systems' new Generation Refiner / Conche at Andina Pack Corferias, Bogota, Colombia, 19th – 22nd November 2019. MacIntyre Chocolate Systems will feature on the Soltecal SAS stand in Hall 11-16, Stand 1009.

The New Generation Refiner / Conche range offers more flexible and enhanced control of the refining process, together with improved design and easier maintenance. With processing capacities from 500Kg up to 5,000Kg, the New Generation range is ideal for both small and large batch production of a variety of products used in the confectionery and savory snacks industry.

MacIntyre at Confitexpo 2019

We are looking forward to exhibiting the new Generation Refiner / Conche at Confitexpo 2019 on 30 July to 2 August at the Expo Guadalajara. Guadalajara Jalisco, México. MacIntyre Chocolate Systems will feature on the CandyTech stand no. 842.

The New Generation Refiner / Conche range offers more flexible and enhanced control of the refining process, together with improved design and easier maintenance. With processing capacities from 500Kg up to 5,000Kg, the New Generation range is ideal for both small and large batch production of a variety of products used in the confectionery and savory snacks industry.

We look forward to meeting you at Confitexpo 2019!

New Generation Refiner/Conche and Artisan Line at ProSweets 2019

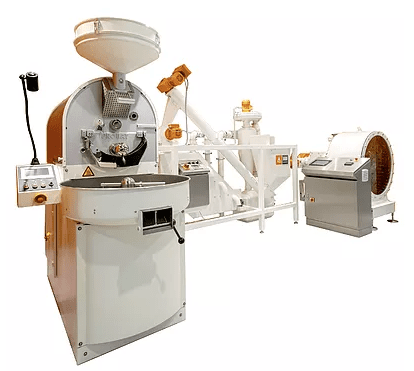

Artisan Line

The Artisan Line is dedicated to providing the highest standards of quality and flexibility. It incorporates roasting, winnowing, liquor grinding, chocolate refining and conching, in a single compact production line for the manufacture of fine chocolate mass using raw cocoa beans

Fine chocolate making is the theme of the MacIntyre Chocolate Systems Ltd stand at ProSweets 2019. It will feature the first public showing of MacIntyre's New Generation Refiner / Conche, the leading and simplest method of mixing, refining and conching fine chocolates and fat based masses, on stand D081. It is available alone or as part of their Artisan Line - a complete system for cocoa bean to liquid chocolate.

The New Generation Refiner / Conche range offers more flexible and enhanced control of the refining process, together with improved design and easier maintenance. With processing capacities from 500Kg up to 5,000Kg, the New Generation range is ideal for both small and large batch production of a variety of products used in the confectionery and savory snacks industry.

The MacIntyre Refiner / Conche range provides production with a particle size as low as 15 microns with flavor developed in line with the vision of the manufacturers. Be in mellow or strong cocoa notes, the New Generation MacIntyre Refiner / Conche wants to provide customers with the flexibility to produce their unique creations. Artisanal bars in addition to producing compounds, ice cream coatings, chocolate spreads, yoghurt coatings, and sweet and savory creams.

MacIntyre Announces New Generation Refiner/Conche Range

The MacIntyre Refiner / Conche range is the leading and simplest method of mixing and refining fat based masses, in addition to producing smooth and condensed chocolate with particle size as low as 15 microns. The New Generation MacIntyre Refiner / Conche willingly grinds nuts into paste and thus cocoa nibs into liquid chocolate for bars in addition to producing ice cream coatings, chocolate spreads, yoghurt coatings, and sweet and savory creams.

More flexible control

With the New Generation Range, MacIntyre has expanded the capability of the Refiner / Conche PLC software to include multi-step programming. A product specific set of process parameters or 'recipes' can be stored in the PLC allowing the correct set of process parameters for a given product to be used with a single touch of the control panel screen.

The New Generation Refiner / Conche's control panel screen also features a comprehensive suite of control and monitoring functions including maintenance, storage and download of actual run data. As well as accurate control of water and product temperatures, the new generation range features a 'non-contact' transducer which is used to control and monitor the system's refining pressure, creating a virtual scale on the machine's control panel.

New design

With the New Generation Refiner / Conche range, MacIntyre introduces its first machines made using advanced technology for castings with increased strength and durability. The introduction of a pressurized air seal, and redesigned sealing assemblies. For quicker and easier commissioning of the Refiner / Conche, a Hygienic Cable System has been introduced for trouble-free installation.

Joe Gorman, operations director, MacIntyre Chocolate Systems, says, "With well over 100 years experience in chocolate manufacture, the MacIntyre Refiner / Conche has consistently set the standard for production of high quality chocolate and compounds. The scope for the refiner / conche in the savory and bakery markets. "

- 1